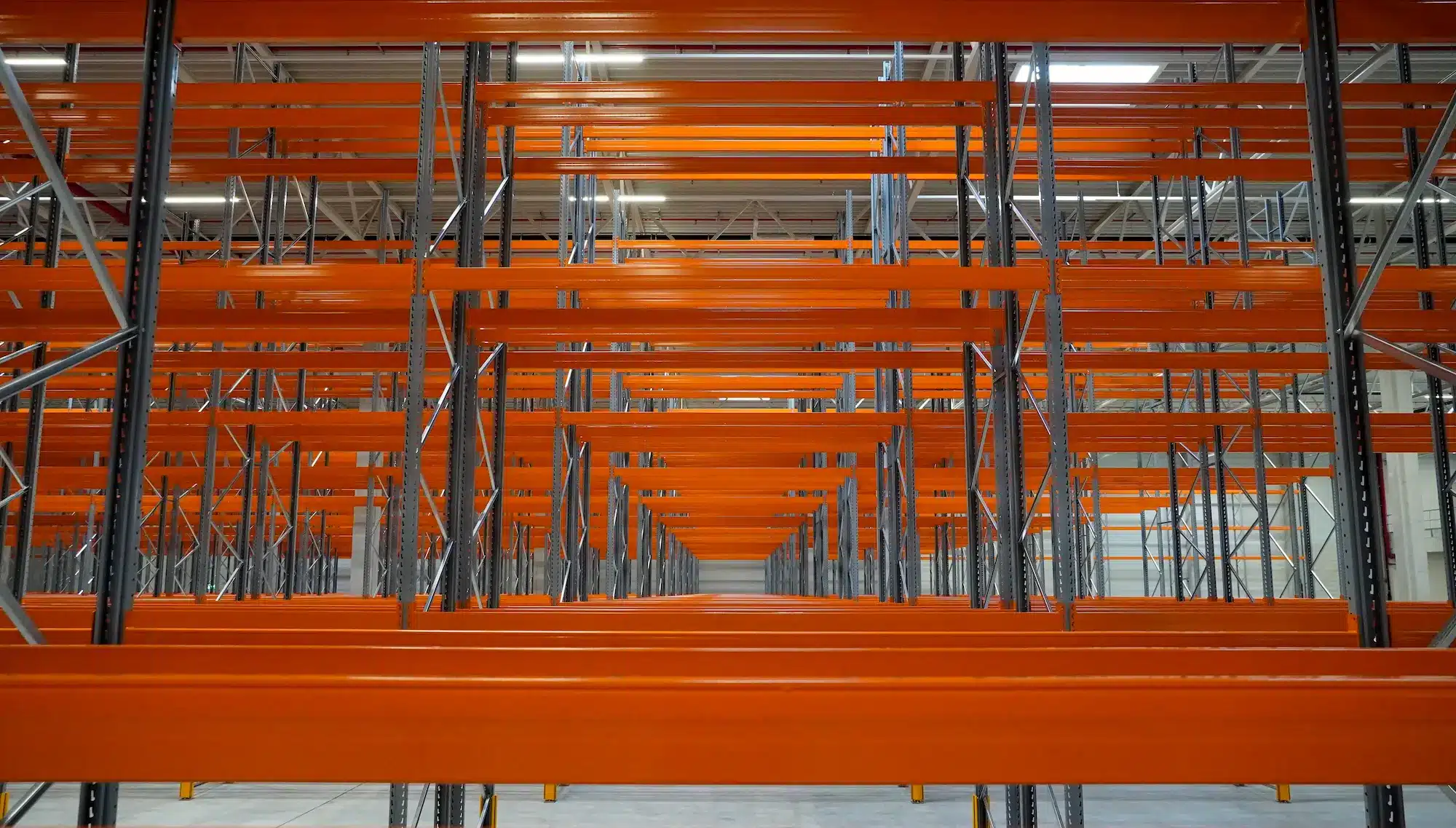

Industrial Pallet Racks for Warehouse Storage Types, Benefits & Tips

Contents

In today’s increasingly competitive industrial landscape, warehouse management isn’t just about having the most space—it’s about using your space the most efficiently to manage your inventory accurately, quickly, and also with safety first.

A key element for high overall storage operations standard is the Industrial Pallet Racking System, also known as warehouse racking or pallet shelving, specifically designed for warehouse use.

Here we will cover everything you need to know before installation, from types of pallet racking, benefits, key features, selection tips, and professional warehouse layout strategies used by B2B businesses to help you choose the best and safest racking solution that fits your budget.

Why are Industrial Pallet Rackings Needed in Industrial Warehouses & Factories?

Pallet racking systems don’t just organize warehouses – they help increase efficiency in your logistic processes in many ways.

- Maximize Space – Store products vertically to utilize warehouse space to its full potential without expanding the facility.

- Faster Product Picking – Reduce lead time with easy pallet access and systematic SKU management, ensuring smooth internal logistics.

- Heavy-Duty Load Capacity – Industrial-grade pallet racking systems can support ton-level loads per shelf, maximizing the amount of products that can be stored.

- Suitable for All B2B Industries – Including manufacturing plants, warehouses, distribution centers, spare parts, construction equipment, food industry, and cold storage.

Types of Industrial Pallet Racking

1. Selective Pallet Rack – Most Popular in Thai Warehouses

Highlights: 100% pallet accessibility, flexible level adjustment, lowest cost of all the pallet rack options. Ideal for business with an overwhelming amount of SKUs such as e-commerce, spare parts, general factories, or automotive parts.

2. Drive-In / Drive-Through Rack – Maximum Space Utilization for Large Warehouses

Highlights: Uses 70-80% more space than Selective Pallet Rack due to the need for forklift aisle space, though rear pallet access is more difficult. Perfect for storing large quantities of identical products, but not suitable for products requiring frequent picking of multiple SKUs.

3. Push Back Rack – Deep Storage with Fast Picking

Highlights: Faster loading and unloading than Drive-In, space-efficient, strong structure, works well with forklifts. Ideal for LIFO inventory rotation.

4. Pallet Flow Rack – Automatic FIFO Flow System

Highlights: Full FIFO support, easy stock picking, no products stuck in the back. Uses gravity to flow pallets from back to front. Perfect for products with expiration dates such as cold storage, fresh food, beverages, pharmaceuticals.

5. Cantilever Rack – For Oversized Long Products

Highlights: No center columns, allowing safe and convenient storage of long products with high load capacity. Ideal for long items such as steel, pipes, lumber, and paper rolls.

Comparison Table of Pallet Rack Types

| Rack Type | Product Access | Space Efficiency | Approximate Price | Suitable Warehouse Type |

| Selective | Easy | Moderate | Low | High SKU warehouses |

| Drive-In | Difficult | Very High | Medium | Large quantities of same product |

| Push Back | Moderate | High | Medium-High | Fast-moving products |

| Pallet Flow | Easy (FIFO) | High | High | Food/pharma/cold storage |

| Cantilever | Moderate | Moderate | Medium | Long/oversized products |

Tips for Choosing Cost-Effective Pallet Racking for Your Warehouse

Selecting industrial pallet racking isn’t just about price – multiple factors including product weight, workflow, and warehouse equipment are crucial to maximize efficiency, reduce risk, and save longer term costs. These tips will help you choose the right pallet racking system from the get go.

1. Start with Detailed Product Assessment

First you must know your products well, as pallet racking is designed to support different weights and product characteristics. Key considerations include:

-

- Pallet Weight – Calculate average weight per pallet and maximum possible weight for engineers to design safely without risk of damage or collapse.

- Dimensions (Width x Length) – Standard sizes like 100×120 cm, 110×110 cm, or custom sizes by industry. This data determines beam width and rack structure.

- Product Height – Different products require different heights (boxes, sacks, oil drums, IBC tanks, etc.), affecting shelf spacing and number of levels per upright.

- Inventory Rotation Type (FIFO/LIFO)

- FIFO – Use Pallet Flow or Selective

- LIFO – Use Push Back

- Large quantities of same product – Drive-in Rack

2. Choose Racks Compatible with Your Forklift

Each forklift type has specific limitations for turning radius, mast height, and aisle space.

Forklift types include:

- Counterbalance Forklift – Requires wide aisles

- Reach Truck – Suitable for high warehouses, operates in narrow aisles

- Stacker – Lower weight capacity, suitable for light warehouses

Key considerations

- Turning Radius – Allow space for safe forklift entry without hitting columns or shelves

- Mast Height – Must match pallet rack height; if racks are too high, products become inaccessible

- Aisle Space – Determines whether Selective or High-Density Rack systems work best

3. Look for Factory-Standard Racking

Material quality should always be a non-negotiable, especially for pallet racking supporting multiple tons of products per structure.

- Industrial-Grade Steel Thickness: Thicker steel provides more strength, less likelihood of column and beam bending.

- International Standard Load Capacity: Manufacturers should clearly specify Load Capacity with “Maximum Load” labels on every rack point.

- Powder-Coated or Galvanized: Prevents rust from moisture and certain chemical exposure, extending rack durability.

- Actual Load Testing: Double checking that the racks actually support the stated weights to be most certain and minimize the risk of collapse.

How Else Can You Improve Storage Efficiency with Industrial Pallet Racking?

- Use Barcode or RFID systems for the most accurate inventory tracking. Avoid human errors.

- Install Rack Guards and Upright Protectors for additional safety standards.

- Inspect pallet rack structure at least every 6 to 12 months with a clear checklists such as check bolts, support columns, and structure in order prevent accidents and damages.

- Design Warehouse Layout to Match Workflow. Dividing product zones by category to reduce worker walking/picking time.

-

- Receiving Zone – Should be near warehouse entrance to reduce product transfer time to racks

- Storage Zone – Position pallet racking according to product type; fast-moving items at the front, slow-moving items deeper

- Picking Zone – For piece-picking, medium racks may be suitable

- Loading Dock – Should have space for order preparation to avoid vehicle waiting times

FAQ

Q: What weight capacity do industrial pallet racks typically support?

A: 500 to 2,000 kg per level, depending on steel thickness and structure.

Q: What type of pallet racking should small warehouses use?

A: Selective Rack is the best choice – flexible, low cost, and easy to design.

Q: What is the difference between Drive-In and Push Back racks?

A: Drive-In allows forklifts to enter deep storage spaces. Push Back loads from the front and automatically slides back.

Q: How often should warehouse racking be inspected?

A: At least every 6 months, with a standardized checklist, and immediately after any rack column impact.

Industrial Pallet Racking is a Worthy Investment that Saves Long-Term Cost

By now you understand that pallet racking plays a main role in driving the entire logistics system to work faster, more accurately, and more safely, directly reducing long-term cost and improving business outcomes. If maximum storage efficiency is a goal for your warehouse and factory, choosing standard Industrial Pallet Racking will deliver real value and confidence to your business long-term.

UPR Thailand offers complete warehouse solutions and services for every square meter of your warehouse. All our products are designed to improve efficiency sustainably and optimize costs. Our full-range of services include pallet rental and sales, warehouse equipment, site surveys, storage layout design, rack structure tailored to your product types, professional installation, and after-sales support.

Contact us for professional consultation on how to elevate your warehouse into a profit generating machine!

UPR (Thailand) Co., Ltd.

TEL : +66-2-672-5100

EMAIL : info-thailand@upr-net.co.jp

UPR (Thailand) Co.,Ltd. > Columns > Logistics > Industrial Pallet Racks for Warehouse Storage Types, Benefits & Tips

Contact us

Contact us  Call us

Call us  Line Official

Line Official